China Weld Neck Flange Manufacturer | Quality Industrial Solutions

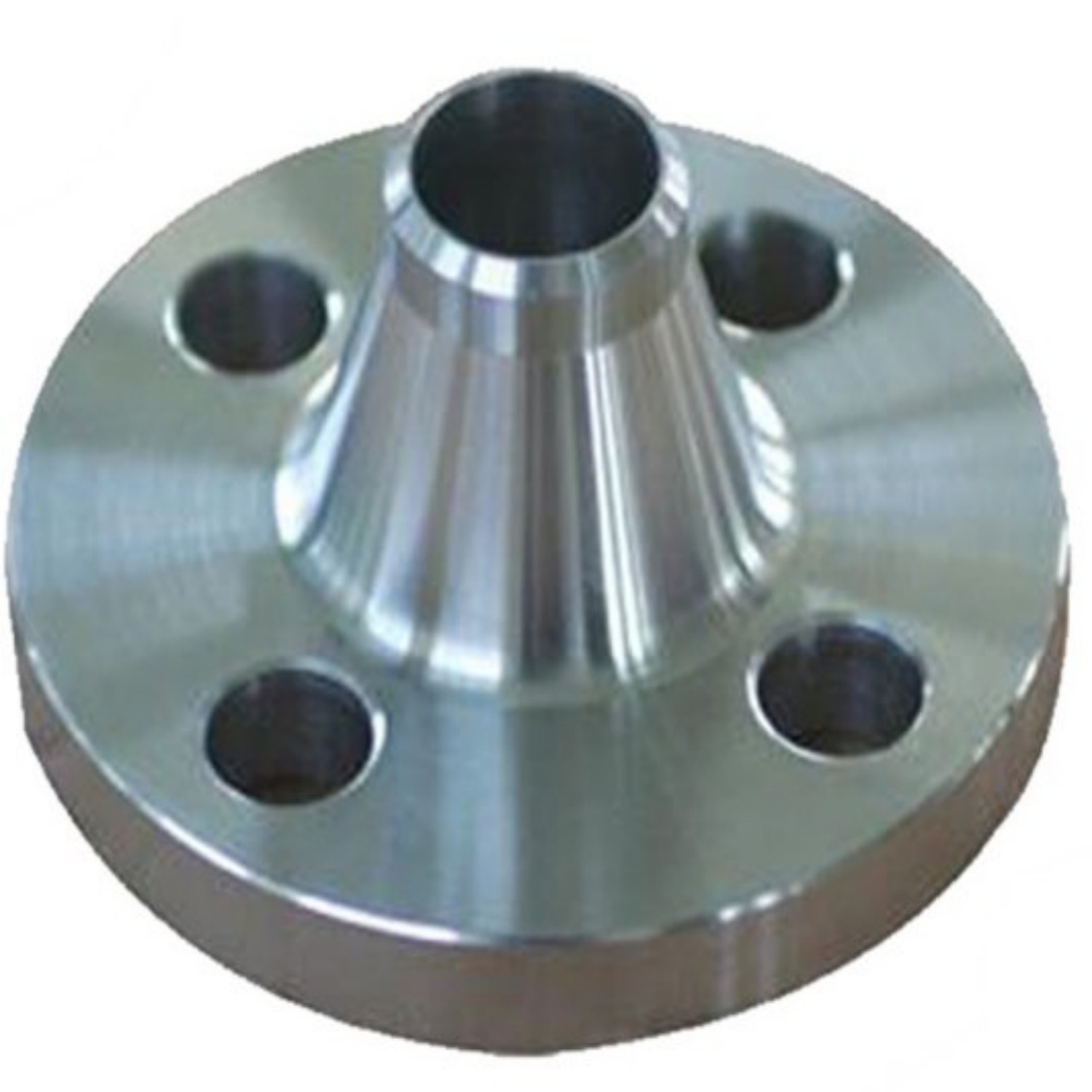

When it comes to high-quality weld neck flanges, I know that durability and performance are key. Our flanges are manufactured in China, ensuring skillful craftsmanship and adherence to international standards. Each weld neck flange is designed for reliable connections in various piping systems, making them ideal for industries like oil and gas, chemical processing, and water treatment. I take pride in the fact that our flanges are made from premium materials, which means they can withstand high pressures and temperatures. As a B2B purchaser, you can trust that our products will meet your specifications and exceed your expectations. Plus, working directly with a reputable manufacturer eliminates middlemen, which can help you save costs. Choose our weld neck flanges for your next project and experience the difference that quality can make. I’m here to assist you with any inquiries, ensuring you get the right solutions for your needs.

weld neck flange Industry Giant Where Innovation Meets 2025

In the ever-evolving landscape of the flanges industry, the weld neck flange stands out as an essential component for ensuring the integrity and efficiency of pipeline systems. As we approach the innovations that 2025 holds, we witness a surge in demand for high-quality, technologically advanced weld neck flanges that can support diverse applications across various sectors, including oil and gas, chemical processing, and water treatment. The ability to combine superior materials with cutting-edge manufacturing techniques is key to meeting global quality standards and addressing the rigorous demands of modern infrastructure projects. The future of the weld neck flange market lies in innovation, with a focus on enhancing performance, durability, and sustainability. Companies are increasingly adopting advanced engineering practices, including CAD technology and precision forging, to produce flanges that offer superior resistance to corrosion and temperature variations. Additionally, the rise of smart manufacturing technologies, such as IoT and data analytics, enables real-time monitoring of production processes, ensuring consistency and reliability across product lines. As global purchasers seek reliable partners in this industry, the emphasis on quality assurance and certification becomes paramount in building trust and long-lasting business relationships. In this competitive landscape, understanding the unique needs of different markets is essential. As industries worldwide embrace digital transformation and strive for more efficient operations, the demand for innovative weld neck flanges continues to grow. Through relentless dedication to product development and a commitment to customer satisfaction, the industry is poised to deliver solutions that not only meet but exceed expectations, setting the stage for a prosperous 2025 and beyond.

Weld Neck Flange Industry Giant Where Innovation Meets 2025

| Dimension | Material | Standard | Pressure Rating | Applications |

|---|---|---|---|---|

| DN50 | Stainless Steel | ASME B16.5 | 150 | Chemical Processing |

| DN80 | Carbon Steel | API 605 | 300 | Oil & Gas |

| DN100 | Alloy Steel | DIN 2633 | 600 | Power Generation |

| DN150 | Duplex Stainless Steel | ANSI B16.47 | 900 | Marine Applications |

| DN200 | Nickel Alloy | BS 3293 | 1500 | Pharmaceuticals |

Related Products