Famous Slip On Flange Suppliers: Quality and Reliability Guaranteed

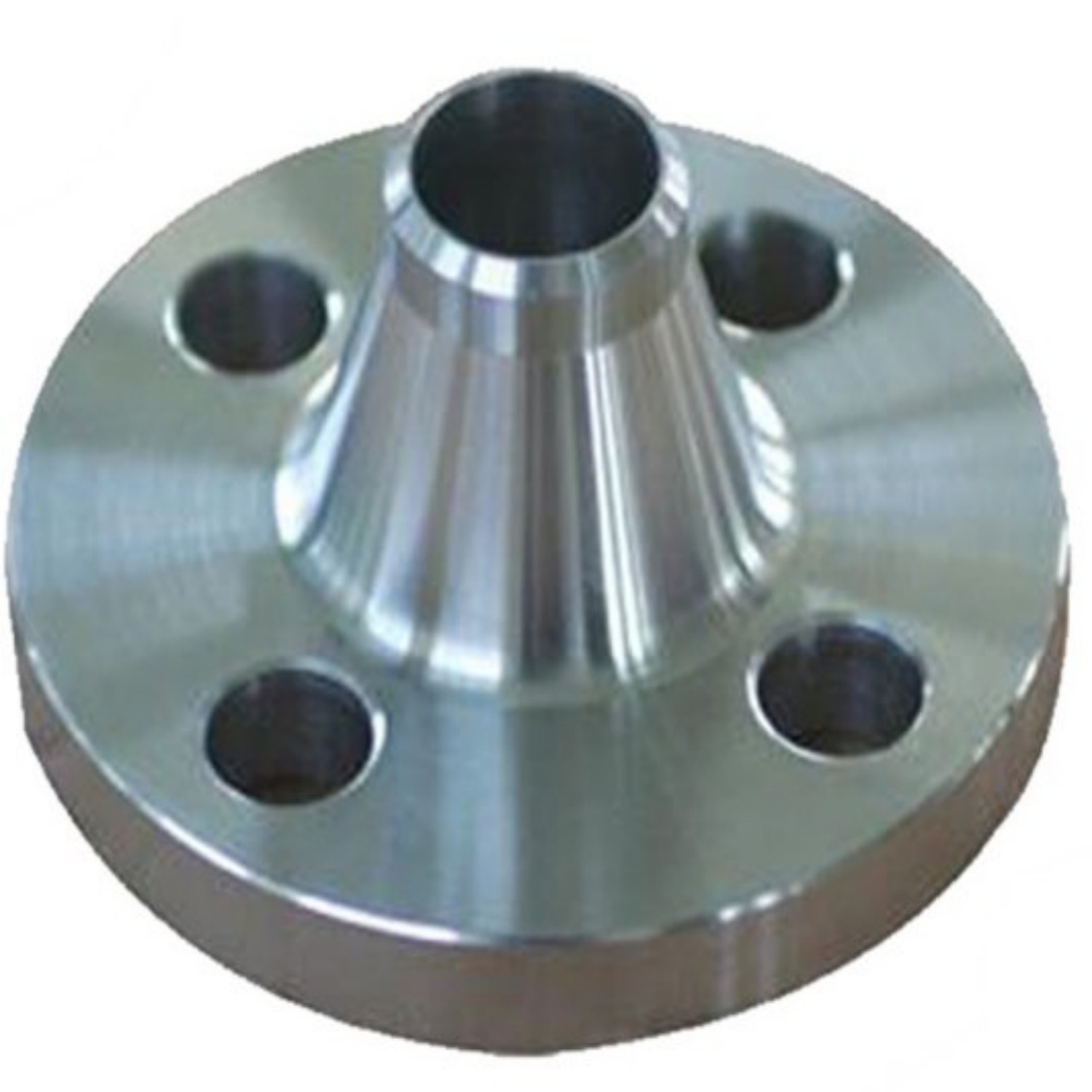

When it comes to reliability and performance, slip on flanges are an essential component for many industrial applications. I’ve seen firsthand how these flanges can help streamline your operations and ensure a strong, leak-proof connection between pipes. Our range of slip on flanges is sourced from famous suppliers, guaranteeing you top-notch quality at competitive prices. I appreciate how their robust construction and versatility make them suitable for various projects, from oil and gas to plumbing. With our trusted suppliers, you can expect timely deliveries and excellent customer service. Whether you need standard sizes or custom options, I've found that there's always a perfect fit for your specific needs. Don't settle for less; let’s enhance your operations with our reliable slip on flanges today. Your projects deserve the best.

slip on flange Pioneers in the Field Now Trending

In today's ever-evolving industrial landscape, slip-on flanges have emerged as indispensable components in pipeline construction and maintenance. Their simple design and ease of installation make them a popular choice among engineers and contractors worldwide. As procurement professionals seek to optimize costs and improve efficiencies, understanding the current trends in slip-on flanges is crucial. One of the notable trends is the increasing demand for high-quality materials that enhance durability and performance. Manufacturers are focusing on integrating advanced materials and technologies to produce flanges that not only withstand extreme conditions but also reduce the risk of leaks and failures. Additionally, the surge in the adoption of corrosion-resistant materials reflects the need for longer-lasting solutions, particularly in industries like oil and gas, water treatment, and chemical processing. Sustainability is another key factor driving the market. Global procurement strategies are increasingly prioritizing suppliers who adhere to environmentally friendly practices in their production processes. As companies aim to lower their carbon footprint, the trend towards eco-friendly options and resource-efficient manufacturing methods is becoming more pronounced. By staying informed about these trends, procurement professionals can make informed decisions that align with both their operational needs and sustainability goals, ensuring the continued success and reliability of their projects.

| Material | Size (inches) | Pressure Rating | Application | Trending Region | Material Grade |

|---|---|---|---|---|---|

| Stainless Steel | 6 | 150lbs | Piping Systems | North America | 316L |

| Carbon Steel | 8 | 300lbs | Oil and Gas | Middle East | A105 |

| Alloy Steel | 4 | 600lbs | Chemical Processing | Asia | B16.5 |

| PVC | 10 | Schedule 40 | Water Supply | Europe | PVC 1120 |

Related Products